PRODUCTS

Introduction of Pulley Lagging Installation Procedures

Hot sulfur type

Traditional vulcanization roller coating

This technology is relatively backward. Due to the low vulcanization pressure and high sulfur content of the roller of the traditional hot vulcanization rubber clad, and the low rubber content of the rubber clad panel, the rubber has poor wear resistance and short service life. It is easy to age under normal working conditions, and the rubber will harden after aging, which leads to the decrease of the adhesion between the conveyor roller and the belt and the decrease of the cleaning function. The roller hot rubber clad technology is backward , the operation is complex, and the site construction cannot be carried out. The cost of hot vulcanization is low, which is the first choice for some manufacturers. In the process of hot vulcanization, the pressure is a little low during vulcanization, which causes the roller out of the hot package to have poor wear resistance, and the long-distance transportation also causes certain cost to the manufacturer, so the share of hot vulcanized rubber is less and less.

Cold sulfur type

New type of cold vulcanization roller rubber coating

The technology of cold coating on site has the advantages of convenient construction on site, high bonding strength, fast curing speed and long service life. The roller rubber rubber plate adopts anti-corrosion and wear-resistant rubber plate, which is compact in material, high in rubber content, excellent in wear-resistant, tensile and tear resistance. Its service life is generally 5-8 times that of the same type of rubber, and it is naturally vulcanized at normal temperature and pressure. This cold vulcanizing adhesive The connection capacity is 7-8 times of that of domestic hot vulcanization coating technology. This roller coating technology is suitable for on-site emergency repair, especially for underground coal mines, small space and other occasions without hot vulcanization coating conditions.

-

On-site training. More insight into the applications, more development.

2019-10-19 -

Safety is no small matter. Make safety your first thought and take precautions from tiny things.

2019-10-19 -

What Is Pulley Lagging

2019-10-21 -

Introduction of Pulley Lagging Installation Procedures

2019-10-21 -

Factors Affecting Wear Resistance of Pulley Lagging

2019-10-21 -

Advantages of Pulley Lagging

2019-10-21 -

Introduction of Wear Liners

2019-10-21

-

Significant Features of Wear Resistant Compound Steel Wear Plate

2019-10-21 -

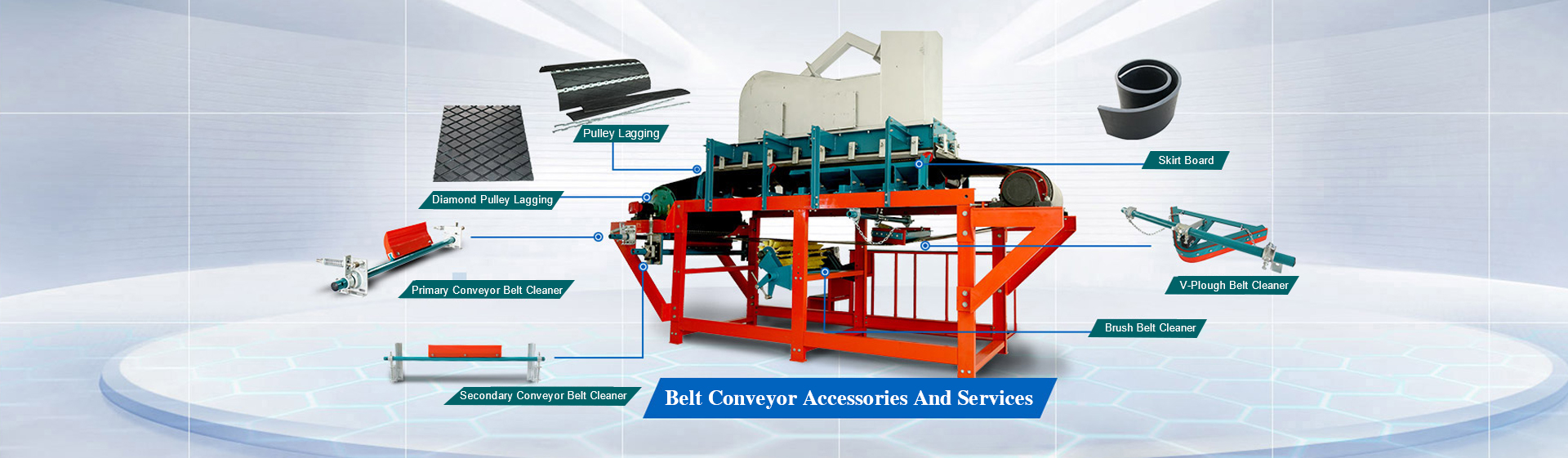

Introduction of Conveyor Skirt Board and How to Install it

2019-10-21 -

Introduction of Belt Cleaner

2019-10-21 -

Features and Types of Belt Cleaners

2019-10-21 -

Introduction of Impact Bed

2019-10-21 -

Advantages of Impact Bed

2019-10-21 -

Design of Impact bed

2019-10-21